Product Introduction

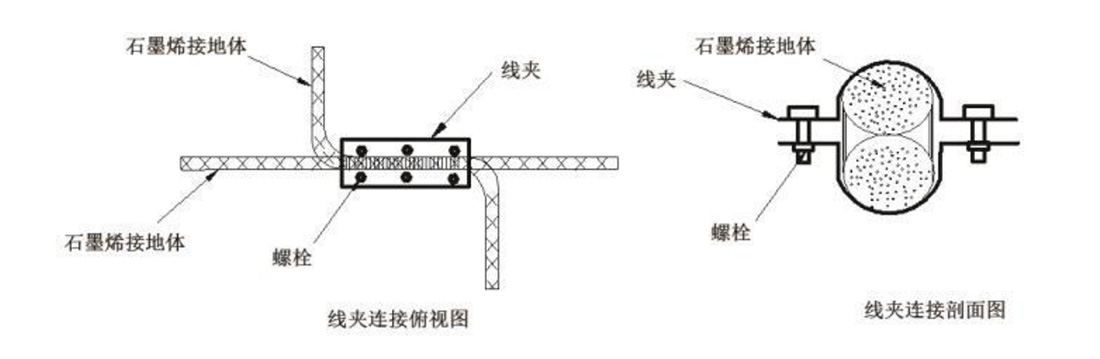

The main component of the absorptive grounding electrode is conductive non-metallic material. Internally, it contains a cable-like graphene lightning protection grounding body. The overall shape is cylindrical, unaffected by water, soil, acidity, alkali, or galvanic corrosion. Its main component is high-carbon graphene, which has stable chemical properties. It is connected to the graphene lightning protection grounding body using a special 316 stainless steel connecting clamp (lap clamp).

Absorptive grounding electrode specifications: ≤100*1000mm. Measured values must not be less than nominal values.

The resistance change rate of the absorptive grounding electrode after a 100kA impulse current withstand test is ≤5%. The resistance change rate of the absorptive grounding electrode after a 30A power frequency current withstand test is ≤5%.

The solid-state resistivity of the absorptive grounding electrode is ≤4×10-5 ≤ 183 µm.

Weight per unit length of the absorptive grounding electrode: 10~11 kg.

Main Standards Followed

The following latest valid standard versions shall be followed, but are not limited to:

GB/T21698-2008 "Technical Conditions for Composite Grounding Electrodes" GB2900.1 "Electrical Engineering Terminology"

GB/T17949 "Guidelines for Measurement of Soil Resistivity, Grounding Impedance and Ground Potential of Grounding Systems"

GB/T16927.1 "High Voltage Testing Technology Part 1: General Test Requirements" GB/T16927.2 "High Voltage Testing Technology Part 2: Measurement Systems"

GB/T50065 "Code for Grounding Design of AC Electrical Installations"

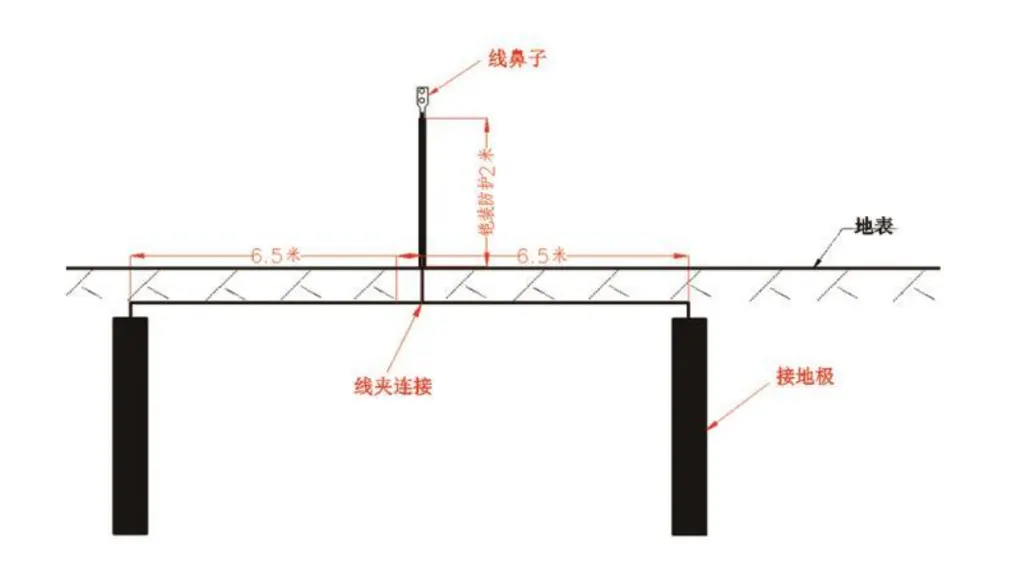

Installation Diagram

Connection Diagram

(Note: Each set of equipment is equipped with one wire lug, a 15-meter graphene grounding electrode, two grounding electrodes, and two sets of connecting clamps. Among them: 1. The wire lug is made of 316 stainless steel; 2. The armored protection includes a 2-meter braided 316 stainless steel protective layer and an outer insulating sheath to enhance its resistance to external damage; 3. The clamps are made of 316 stainless steel to enhance corrosion resistance.)

Technical Parameters

| Test Items | Acceptance Items (Type Test) |

Sampling Inspection Items | Technical Requirements |

| Error between measured and nominal diameter | √ | √ | Error ≤5% |

| Resistivity of Grounding Electrode | √ | √ | ≤3×10⁻⁶ Q ⁻¹ m |

| Connection Resistance | √ | ≤4m ⁻¹ | |

| Grounding Electrode Impulse Current Withstand Test | √ | width="138" >100kA, ≤5% | |

| Grounding electrode power frequency current withstand test | √ | 30A, ≤5% | |

| Corrosion test | √ | ≤10% | |

| Bending, tensile, and torsional strength test | √ | √ | △R%≤10% |

| Flame retardant performance | √ | FV-0 grade |

Note: (1)△R% is the resistance change rate (test value relative to the resistance value indicated on the product nameplate).