Detailed Introduction

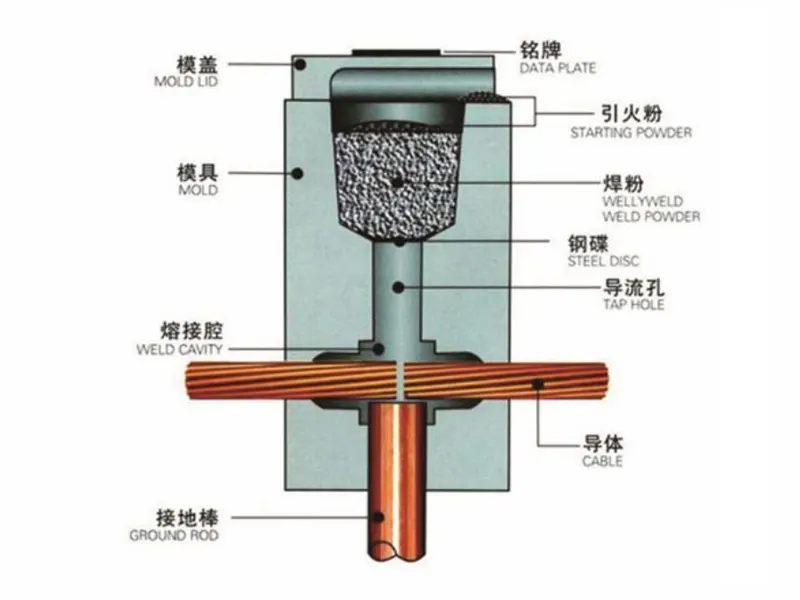

The mold consists of several parts, including a mold cover, mold cavity, welding cavity, guide groove, and mold clamp. It can withstand the melting temperature of metals such as copper, steel, and iron, as well as the flow direction, flow rate, and final shape of the molten metal. Through scientific and rigorous design, it uses triple-impregnated, four-fold pure graphite as raw material, which has high density and good wear resistance. It is processed using CNC machine tools. The mold design is reasonable, the technology is mature, it has a long service life, is easy to demold, and has good versatility. The typical mold life is 70-120 cycles.

Instructions for Using the Exothermic Welding Mold

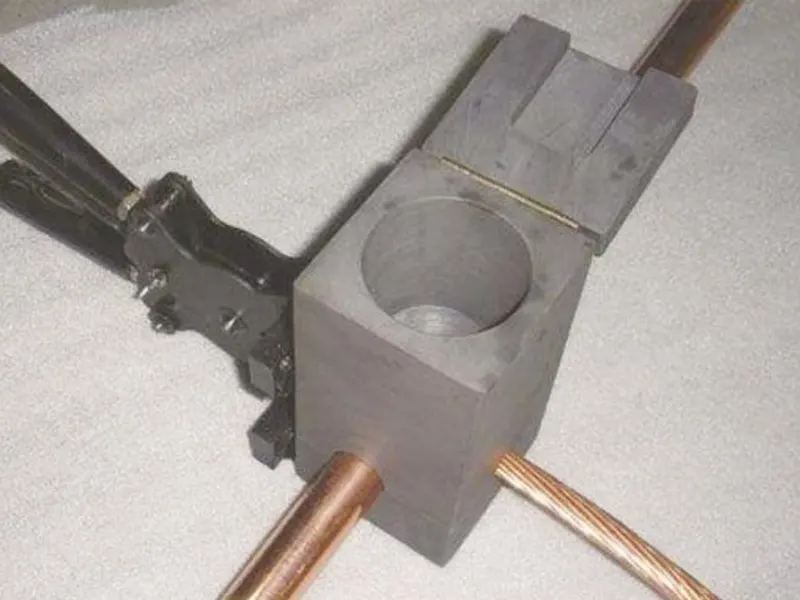

Step 1: Clean the exothermic welding mold. Remove moisture from the mold using heating. Then, place the cleaned metal conductor into the mold and clamp it tightly to ensure there are no gaps.

Step 2: Place the metal spacer at the bottom of the reaction chamber of the exothermic welding mold.

Step 3: Introduce the welding powder into the reaction chamber, leaving some ignition powder on the mold lip.

Step 4: Cover the exothermic welding mold and ignite the ignition powder on the mold lip with an ignition gun.

Step 5: The reaction is underway. Wait until the molten metal completely solidifies.

Step 6: Open the exothermic welding mold and clean it for future use. A complete exothermic welding connector is now manufactured.

Selection of Welding Powder and Mold Clamps

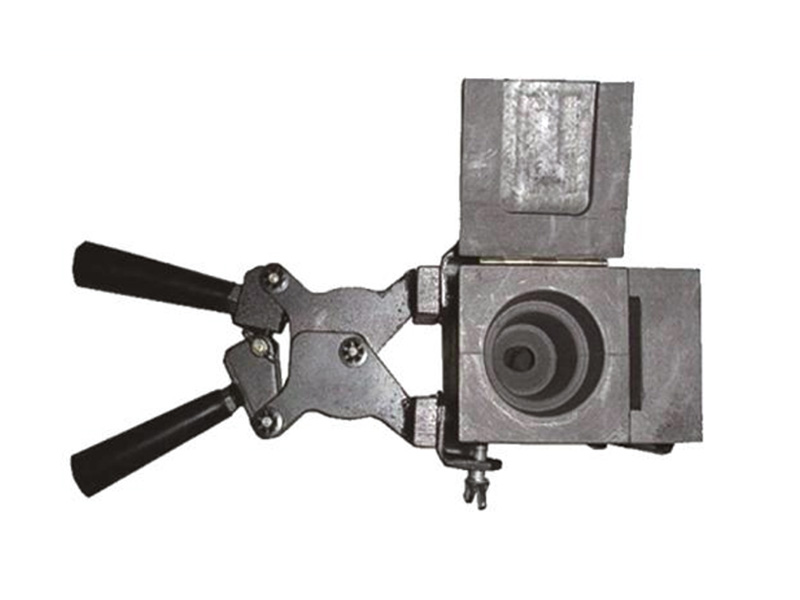

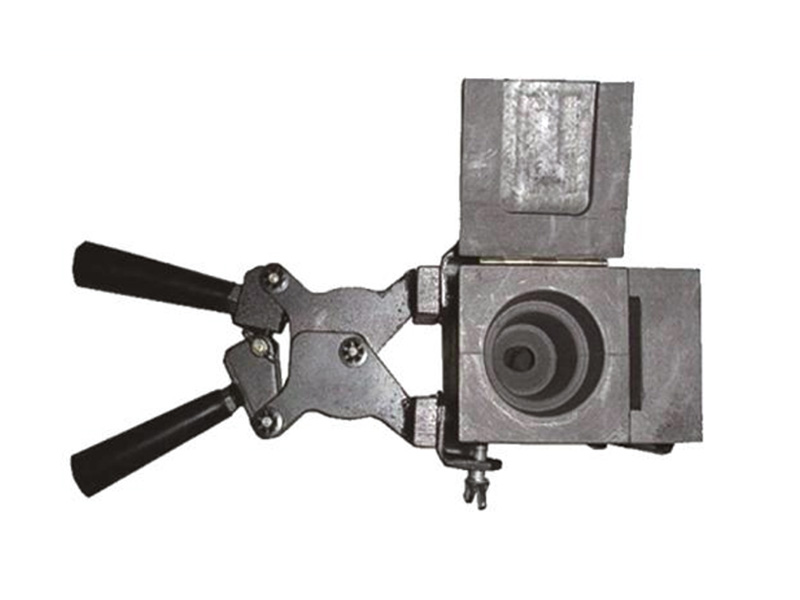

Welding powder and mold clamps are essential materials used in conjunction with molds. The welding powder type must match the type indicated on the mold's nameplate. Commonly used welding powder types are 90#, 115#, 150#, 200#, 250#, and 300#. Mold clamps come in two types: standard and eccentric. Standard clamps are suitable for most molds, while eccentric clamps are mainly used for welding grounding rods, cross welding, and other types where it is necessary to avoid the welding material. Some mold models require auxiliary clamps such as F-clamps and C-clamps.

Precautions for Exothermic Welding Important Notes

1. Before operation, ensure the parts to be welded are free of contaminants, and that there are no weld slag chunks or powder left from previous welding in the mold cavity and casting mold.

2. Before operation, use a blowtorch (or gas torch) to dry the parts to be welded and the mold as much as possible to remove moisture,

to prevent the mold from cracking during use.

3. During operation, before ignition, ensure the mold cover is closed and there are no gaps at the mold closure point. Ensure the welding point of the parts to be welded is centered in the cavity.

4. During operation, no unauthorized personnel should remain within 1.50 meters of the work site.

5. During operation, no flammable materials should be placed within 1-2 meters of the work site.

6. Operators must wear work gloves with a certain degree of heat insulation.

7. Operators must not face the mold opening during operation;

8. Upon ignition, if the ignition powder is ignited, the operator must immediately move at least 1.50 meters away from the casting mold;

9. After the exothermic flux reaction is complete, allow the mold and the workpiece to cool naturally for 10-20 seconds;

10. Insulation of the workpiece must only be performed after the conductor has completely cooled.

Selection of Welding Powder and Mold Clamps

Welding powder and mold clamps are essential materials used in conjunction with molds. The welding powder type must match the type indicated on the mold's nameplate. Commonly used welding powder types are 90#, 115#, 150#, 200#, 250#, and 300#. Mold clamps come in two types: standard and eccentric. Standard clamps are suitable for most molds, while eccentric clamps are mainly used for welding grounding rods, cross welding, and other types where it is necessary to avoid the welding material. Some mold models require auxiliary clamps such as F-clamps and C-clamps.