Application Scope

Widely applicable to anti-corrosion grounding, anti-static grounding, protective grounding, and working grounding in petrochemical plants, oil depots, power plants, substations, transmission line towers, communication base stations, airports, railways, various high-rise buildings, microwave relay stations, network computer rooms, and other places.

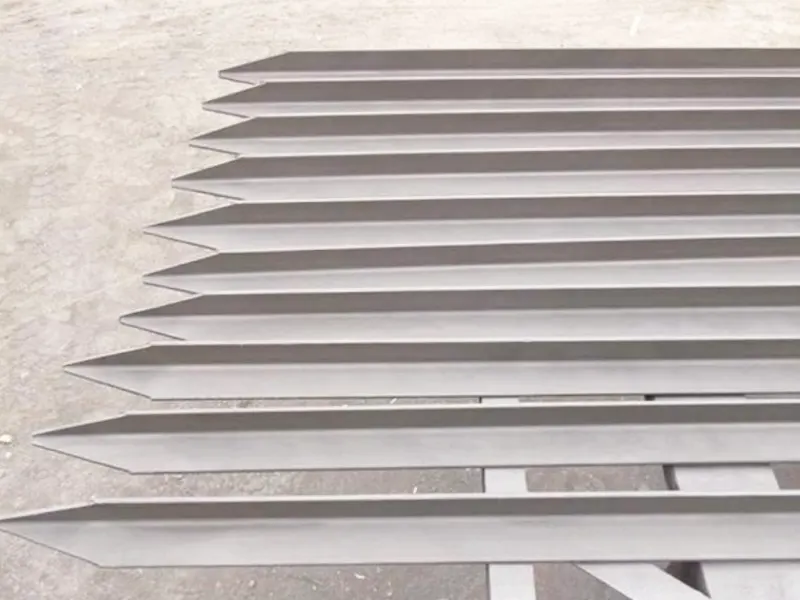

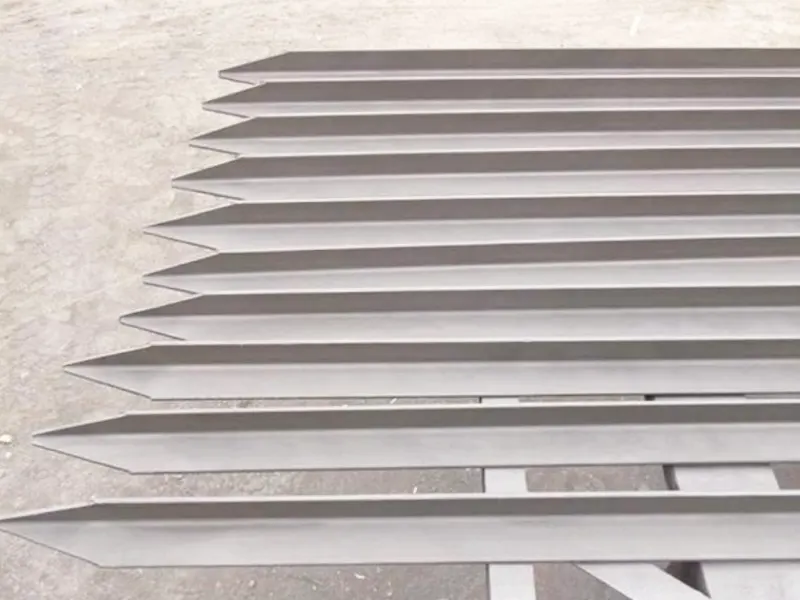

Product Features

1. The nano-carbon reinforced grounding device uses hot-dip galvanized flat steel as the main material, possessing the high strength and thermal stability of steel, while zinc provides cathodic protection.

2. Nano-carbon, as the coating material, has five times the corrosion resistance of steel and excellent electrical conductivity.

3. The hot-dip galvanized flat steel coated with nano-carbon has strong corrosion resistance and a service life of over 50 years, essentially achieving lifetime maintenance-free operation.

4. Convenient construction and simple operation; can be achieved using general metal welding methods.

5. Compared to pure copper and copper-clad steel products, it offers better cost performance.

Technical Parameters

1. Resistivity at room temperature: ≤0.5 μm

2. Adhesion: Grade 1

3. Salt and alkali resistance: No swelling after immersion in 10% NaCl solution and 10% NaOH solution for 1000 hours each.

4. Average coating thickness ≥150µm

5. No burning or peeling of the coating under high current impact (30KA/2S).

6. Smooth appearance, no delamination, peeling, or cracking.

Construction Methods

1. The burial depth of the vertical grounding electrode should not be less than 0.8m from the top.

2. The burial location of the grounding electrode should not be less than 1.5m from the building. When encountering sand, gravel, garbage, ash, etc., the soil should be replaced and compacted in layers.

3. When using welding for connection, the weld should be full and have sufficient mechanical strength, free from defects such as slag, cracks, incomplete welds, and porosity. After cleaning the slag residue at the weld, apply a special anti-corrosion coating for corrosion protection. When overlapping, the flat steel should be at least twice the width, and the round wire at least six times the diameter for welding [special coating, available from the manufacturer].

4. After drilling holes at the grounding electrode locations according to the design requirements, insert the nano-carbon grounding electrode. The installation of the nano-carbon grounding electrode must not be done by hammering. After the grounding electrode is installed in the mounting hole (well), the backfill soil should not contain sand, gravel, or construction waste. The backfill soil should be compacted in layers.

5. Fill and compact the soil to ensure close contact between the grounding electrode and the soil. Leave approximately 20cm at the top for connection to the horizontal grounding wire and perform inspection.

6. Lay the horizontal grounding wire connecting the nano-carbon grounding electrodes. Before laying, straighten the wire, then place the nano-carbon grounding steel in the trench. Connect the horizontal wire to the nano-carbon grounding electrode using the designed connection method. Flat nano-carbon grounding wires should be laid on their side, not flat. When connecting by welding, remove the welding slag after welding and apply a surface anti-corrosion coating to the welded and damaged areas using the manufacturer's specified process. Leave sufficient connection length at the point where the grounding wire needs to be led out.

7. Exposed grounding wires should be painted black, with even and complete application, but do not paint the termination clips and grounding terminals.

8. After connection is completed, (material, location, welding quality, cross-sectional specifications, etc.) must meet the design and construction acceptance requirements. Backfilling can only proceed after inspection and approval. The material must be compacted in layers, and the grounding resistance measurement value must be recorded on the inspection record sheet.

9. Material handling precautions: When using nano-corrosion-resistant composite flat steel and nano-corrosion-resistant composite grounding electrodes, to protect the surface anti-corrosion coating, at least two people must carry them to the construction site. Do not drag them on-site.

Specifications and Models

| Name | Specifications | Supply Length |

| Nano-carbon composite anti-corrosion grounding wire/flat steel | 25×4mm | 6 meters/piece |

| Nano-carbon composite anti-corrosion grounding wire/flat steel | 40×4mm | 6 meters/piece |

| Nano-carbon composite anti-corrosion grounding wire/flat steel | 50×5mm | 6 meters/piece |

| Nano-carbon composite anti-corrosion grounding wire/flat steel | 60×6mm | 6 meters/piece |

| Nano-carbon composite anti-corrosion grounding wire/flat steel | 70×7 mm | 6 meters/piece |

| Nano-carbon composite anti-corrosion grounding wire/flat steel | 80×8mm | 6 meters/piece |

| Nano-carbon composite anti-corrosion grounding electrode (angle steel) | 50×50×5 | 2.5 meters/piece or 3 meters/piece |

| Nano-carbon composite anti-corrosion grounding electrode (angle steel) | 60×60×6 | 2.5 meters/piece or 3 meters/piece |

| Nano-carbon composite anti-corrosion grounding electrode (angle steel) | 63×63×6 | 2.5 meters/piece or 3 meters/piece |

| Nano-carbon composite anti-corrosion grounding electrode (angle steel) | 75×75×8 | 2.5 meters/piece or 3 meters/piece |