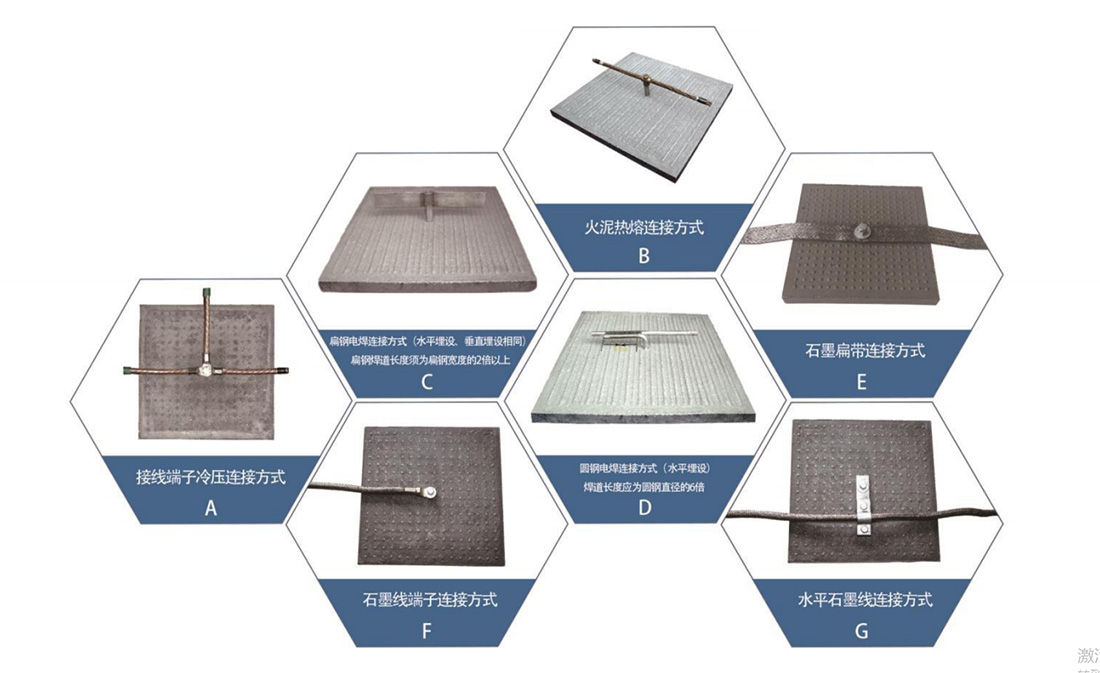

Detailed Introduction

XCL High-Precision New Material Series Grounding Electrodes utilize high-strength non-metallic grounding electrodes produced through high-carbon crystallization and patented processes, increasing resistance reduction by approximately 30% (compared to metal grounding electrodes invented in the 18th century). Soil conductivity is primarily based on ionic dielectric displacement current conduction, supplemented by metallic mineral contact electron conduction. This is because metallic grounding electrodes only possess the single function of contact electron conduction and lack the dielectric ionic displacement current function. REX Rexite, however, possesses both of these conductive functions, perfectly matching the conductivity of soil, thus increasing its resistance reduction effect by approximately 30%.

Three Major Advantages of the New Generation Product

1. 30% Increase in Resistance Reduction

XCL High-Precision New Material Series Grounding Electrodes and Modules are made of natural conductive minerals molded in one piece under high pressure using a hydrogel silicate matrix. Compared with metal grounding bodies, XCL High-Precision New Material Series Grounding Electrodes and Modules offer a 30% increase in resistance reduction for the same area. Compared with copper-clad steel grounding rods, they cost approximately 50%, saving 50% of construction costs.

2. High Strength, Small Size, Light Weight, Reduced Transportation and Construction Costs

XCL High-Precision New Material Series Grounding Electrodes and Modules are high-strength, small in size, and lightweight, making them the easiest to install among similar products. Their user-friendly packaging also allows for successful installation in environments inaccessible to construction machinery. 3. Non-corrosive, non-toxic, eliminating environmental maintenance costs and reducing operating costs.

XCL high-precision new material series grounding electrodes are made of hydrated, non-corrosive (resistant to soil acid and alkali corrosion), and non-toxic materials, making them suitable for any environment. After installation, they will not pollute groundwater sources, exhibiting excellent environmental protection characteristics.

Nine Key Features of the New Generation Product

1. Raw Material Composition: Carbon crystals, natural conductive minerals, hydrogel silicates;

2. Conductivity: Resistance reduction effect increased by 30%;

3. Stable Resistance: Low water absorption rate, grounding resistance value is highly stable regardless of soil moisture;

4. Cost Saving: Compared with copper grounding materials, it can save about 50% of the cost;

5. Mechanical Properties: Compressive strength up to 19.6MPa (192 kg/cm²) or higher;

Extremely strong compressive strength;

6. Convenient Transportation: Small size and light weight, using EPE special mold inner packaging and high-quality cardboard outer packaging;

7. Service Life: Up to 100 years;

8. Environmental Performance: Non-corrosive (resistant to soil acid and alkali corrosion), non-toxic, and does not pollute groundwater;

9. High Density Ratio: 1.32 times that of other brands, low porosity, low moisture content, and higher material stability.

450 Carbon Condensed Grounding Electrode Technical Parameters Overview

| Project Name | Testing Technical Parameters | Remarks |

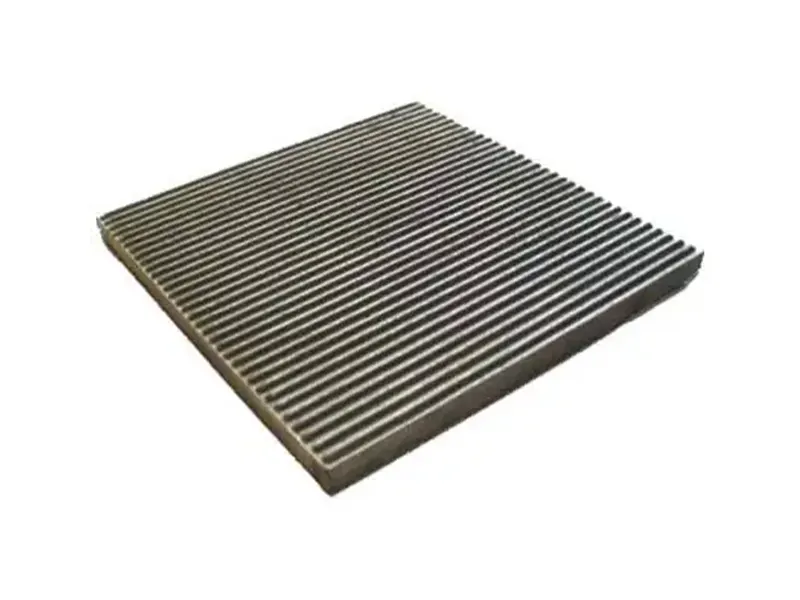

| Product Name | Carbon Grounding Electrode | Straight Corrugated Surface |

| Product Model | -450two | |

| Product specifications | 450×450×35m2 | |

| Single block weight | 14.8kg | 2 pieces/pack |

| Resistivity Measurement Experiment | Resistivity less than 0.0098 .M 2 | Standard requirement less than 30 .M 2 |

| Resistivity Reduction Effect Coefficient Measurement Experiment | Resistivity Reduction Effect Coefficient less than 0.74 | Standard requirement less than 1 |

| Impulse current withstand test | (20KA impulse current test) Average value -9.7% | Standard requirement (1KA impulse current) Not greater than 20% |

| Contact resistance measurement test | 0.80Q | Standard requirement Not greater than 10 Ω |

| Power Frequency Current Withstand Test | Average value -7.5% | Standard requirement: not greater than 20% |

| Compressive Strength | 18.6Mpa | Meets Requirements |

| Corrosion Performance Test | Average Corrosion Rate 0.01mm/Year | Average Corrosion Rate Not Greater Than 0.03mm/Year |

| Core Structure | 316 Stainless Steel Material or Steel Electrode Core | Utilizing a Spiral Cross Structure for Current Dispersion |

| Patent Technology Two | Six National Patents | |

| Product Feature Two | Qualified Product After 20KA High Current Impact Test | National Standard Requirement: 1KA |

| Test Report | 1. Test Report from State Grid Electric Power Research Institute;2. Test Report from National Insulator and Surge Arrester Quality Supervision and Inspection Center;

3. Heavy Metal Test Report from PONY Testing Center. |

|