Product Introduction

This combined copper-clad steel grounding rod is manufactured using a unique production process. It combines the low resistance, strong corrosion resistance, and good electrical connectivity of copper with the high strength and ease of installation of steel, making it an ideal alternative to traditional metal grounding materials. The copper layer is not easily peeled off, has good plasticity, can be threaded, and can be bent, facilitating transportation and installation. It has been widely used in grounding devices for power transmission and communication lines, power stations, buildings, and antennas. It can also be used in grounding systems for electronic equipment such as computers, and can be combined with lightning rods and down conductors to form lightning protection grounding systems.

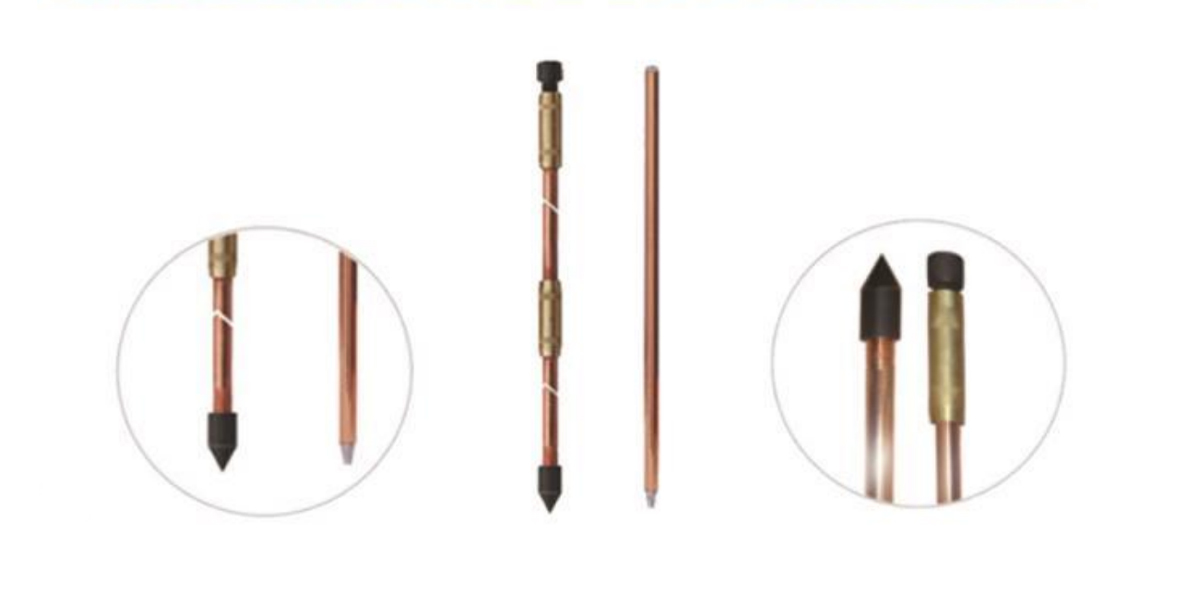

Combined Copper-Clad Steel Grounding Rod Structure

Main Rod: The grounding rod is made of high-quality cold-drawn round steel, and externally cast with copper (thickness above 0.8mm, copper content 99.9%) using specialized equipment to ensure excellent conductivity and mechanical strength. This product has excellent corrosion resistance.

Connecting Pipe: Copper connecting pipes can be used to connect the rods, providing excellent corrosion resistance. The rods are in close contact, and the driving force acts directly on the grounding rod when it is driven into the ground or drilled into the ground using a drive drill. Divided into threaded and non-threaded connections:

Drive head: Made of high-strength alloy steel, ensuring smooth driving force into the ground; Alloy: The combined connector is mainly used for deep well grounding, ensuring successful driving into the ground under complex geological conditions.

Specifications

| Model | Length (mm) | Diameter (mm) | Weight (kg) |

| XCL/GSY-1514 | 1500 | 14.2 | 2 |

| XCL/GSY-2514 | 2500 | 14.2 | 4 |

| XCL/GSY-3014 | 3000 | 14.2 | 4 |

| XCL/GSY-1517 | 1500 | 17.2 | 3 |

| XCL/GSY-2517 | 2500 | 17.2 | 5 |

| XCL/GSY-3017 | 3000 | 17.2 | 6 |

Technical Advantages

1. Unique Manufacturing Process: Utilizing a pioneering horizontal continuous casting process, it achieves metallurgical fusion between copper and steel.

1. Uninterrupted Traction: It can be pulled out of the ground like a single metal without separation, peeling, or cracking.

2. Superior Corrosion Resistance: The composite interface uses high-temperature welding, leaving no residue and preventing corrosion at the joint surface. The thick copper layer (average thickness greater than 0.8mm) provides strong corrosion resistance and a long service life (greater than 40 years), reducing maintenance workload.

3. Excellent Electrical Performance:The excellent conductivity of the surface copper material results in a resistance value far lower than conventional materials.

4. Wide Applicability: This product is suitable for grounding construction under varying soil moisture, temperature, pH, and resistivity conditions.

5. Safe and Reliable Connection: Using dedicated connecting pipes or hot-melt welding ensures a strong and stable joint.

6. Convenient and Quick Installation: Complete accessories and easy installation effectively improve construction speed.

7. Increased Grounding Depth: A special connection and transmission method allows for depths up to 35 meters underground to meet low-resistance requirements in special applications.

8. Low Construction Cost: Compared to the traditional construction method using pure copper grounding rods and grounding strips, the cost is significantly reduced.

Technical Parameters:

1. Copper Layer Thickness: ≥0.8mm

2. Tensile Strength: ≥600N/mm²

3. Straightness Error: ≤1 mm/m

4. Copper Layer Plasticity: When the grounding rod is bent at a 30-degree angle, there are no cracks on the inner and outer edges of the bend.

5. Copper Layer Bonding: Adhesion tests show good copper-steel bonding in the rod body, with no peeling. Grounding rods can be connected to the required length, extending up to 35 meters underground, reducing the impact of climatic conditions (such as frost and drought) on soil resistivity and grounding resistance.

Calculation Formula for Usage

Grounding resistance of a single copper-clad steel grounding rod:

Usage of copper-clad steel grounding rods:

Rt→Grounding resistance of a single copper-clad steel grounding rod (Q) p→Soil resistivity at the construction site (μm)

L→Length of the copper-clad steel grounding rod (m)

d→Diameter of the copper-clad steel grounding rod (m)

n→Usage of copper-clad steel grounding rods (number of rods)

R→Design required grounding resistance (Q)

μ→Utilization coefficient, generally taken as 0.4~0.8