Exothermic Welding Powder

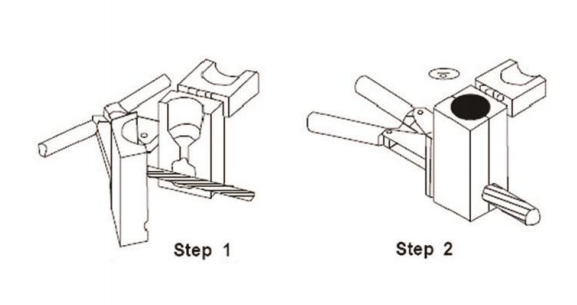

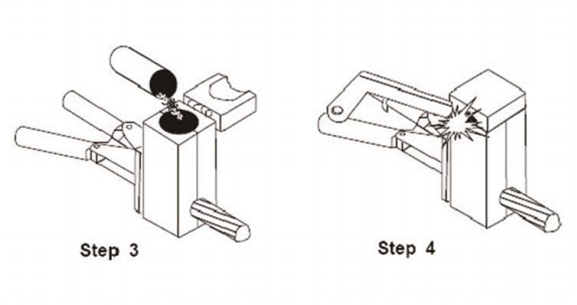

Welding powder is a gray powdery substance. Commonly available grades include: No. 90, No. 115, No. 150, No. 200, No. 250, and No. 300 exothermic welding flux. The grade of the welding powder corresponds to the weight in grams per packet. One packet of exothermic welding flux is used with one packet of initiator and one metal spacer. The welding powder grade must match the grade on the mold nameplate to achieve a high-quality weld.

Welding powder is an essential material for exothermic welding. It achieves a high-quality weld by completely melting the metals through the high temperature generated by the aluminothermic reaction. This reaction takes place within a high-temperature resistant graphite mold. Under normal operating conditions, one mold can weld 70-120 points, and the welding process takes only a few seconds.

Advantages of Exothermic Welding Powder

1. Simple welding method, safe operation, no professional technical knowledge or special protection required, easy to learn;

2. No external energy or power supply required, simple tools and equipment, can be operated independently indoors and outdoors, high construction efficiency;

3. The welding point is high-purity metallic copper, unaffected by corrosive products, with strong corrosion resistance;

4. The welding point is connected by metallic bonds, a permanent molecular bond that will never loosen;

5. Because the cross-sectional area of the welding point is larger than that of the conductor, the current carrying capacity of the welding point is greater than that of the conductor;

6. Exothermic welding powder is true molecular welding, the conductor is not damaged and there is no contact surface, the overall effectiveness of the conductor interface remains unchanged, and the conductivity is equivalent to that of a single copper wire;

7. The welding point can withstand repeated large surge (fault) currents without degradation; 8. Exothermic welding powder has a wide range of applications and can be used for welding copper, copper-clad steel, copper-coated steel, rails, cast iron, niobium, various alloy steels including stainless steel, and high-resistance heating source materials.

Product Applications

1. Horizontal grounding grid connection

2. Signal line connection to oil and gas pipelines

3. Signal line connection to rails

4. Connection to reinforcing bars

5. Connection of lead wires to terminals

6. Other electrical connections