Product Introduction

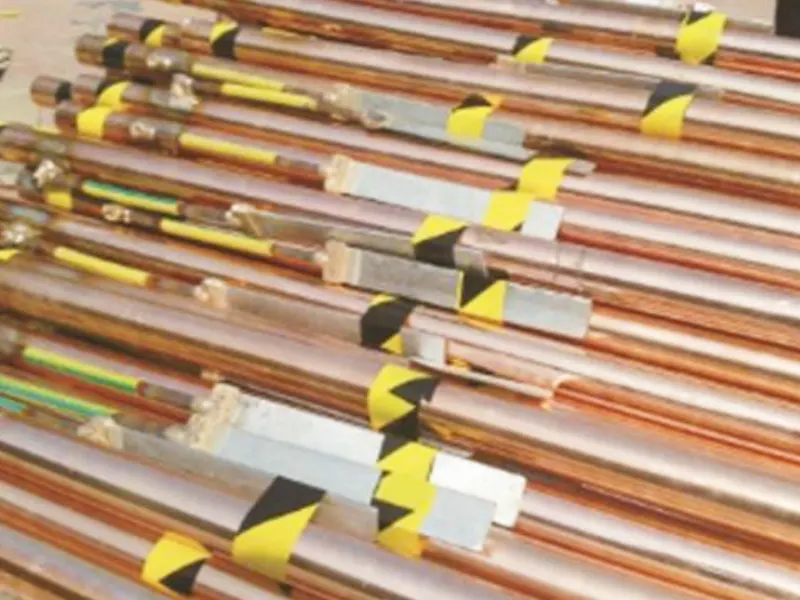

The ion grounding rod system is composed of advanced reversible slow-release compounds. The electrode outer material is pure copper to ensure conductivity and a long service life. Tests have shown that the direct cause of excessively high soil resistivity is the lack of free ions to assist in conductivity. The filler outside the grounding conductor is primarily composed of materials with strong water absorption, strong adsorption, and high cation exchange performance. It is supplemented with various chemical materials that are long-lasting, reduce resistance, have strong anti-corrosion properties, high expansion coefficient unaffected by temperature changes, and are resistant to high-voltage impacts. It is mainly used to solve problems related to temperature, ion generation content, and corrosion protection around the grounding conductor. This ensures a tight bond between the conductor and the earth, thereby reducing the contact resistance between the electrode and the soil, improving the resistivity of the surrounding soil, and effectively enhancing lightning conduction and release capabilities. The internal filling material of the conductor contains special electro-ionic compounds that can fully absorb moisture from the air. Through deliquescence, active ions are effectively released into the soil, reacting with moisture in the soil and air to promote a slow-release and resistance reduction on the conductor's exterior, while maintaining long-term resistance stability. The compounds inside the conductor gradually transform into a gel-like, transparent state over time. We utilize the conductivity of these gel-like compounds to ensure the entire system remains in a state of ion exchange for an extended period, thus forming an ideal ion grounding system.

Product Specifications

| Code | Specifications | Material | Appearance | PH Value | Inrush Current R |

| XCL/GSY-01 | φ50*1000mm | pure copper | Type I | 7+5 | ≤1% |

| XCL/GSY-02 | φ50*1500mm | pure copper | Type I | 7+5% | ≤1% |

| XCL/GSY-03 | φ50*2000mm | pure copper | Type I | 7+5% | ≤1% |

| XCL/GSY-04 | φ50*2500mm | pure copper | Type I | 7+5% | ≤1% |

| XCL/GSY-05 | 54*1500mm | pure copper | Type I | 7+5% | ≤1% |

| XCL/GSY-06 | φ54*2000mm | pure copper | Type I | 7+5% | ≤1% |

| XCL/GSY-07 | φ54*2500mm | pure copper | Type I | 7+5% | ≤1% |

| XCL/GSY-08 | φ54*3000mm | pure copper | Type I | 7+5% | ≤1% |

Product Advantages

1. Ionized compounds penetrate the surrounding soil to improve soil resistivity and enhance conductivity;

2. Low impedance, effectively dissipating lightning and power fault currents;

3. Long-lasting, resistance-reducing, corrosion-resistant, maintenance-free, with a service life of over 40 years;

4. Unaffected by climate change;

5. Small footprint, minimal construction work, and low overall cost;

6. Horizontal L-shaped ion grounding rods are available for locations where deep drilling is not possible;

7. All materials are non-toxic and pollution-free, causing no negative impact on the environment and meeting environmental protection requirements.

Technical Parameters

| Soil | [φ54*3000mm]Number of ion grounding rods under different grounding resistances | |||

| Resistivity | <10Q | <4Ω | <1Ω | <0.5Ω |

| 50 | 1 | 2 | 4 | 6 |

| 100 | 2 | 3 | 6 | 9 |

| 200 | 3 | 5 | 8 | 12 |

| 300 | 4 | 6 | 12 | 16 |

| 500 | 6 | 10 | 16 | 20 |

| 1000 | 8 | 12 | 20 | / |

| 2000 | 12 | 16 | / | / |

| 3000 | 16 | / | / | / |

| 5000 | 20 | / | / | / |

Application Case

| Case Name | Case Application Analysis |

| Power Plant Grounding | Power plant grounding generally requires a strength of less than 0.5 ohms. Traditional grounding construction is difficult and costly. Ion grounding is economical and effective. |

| Hydropower Station Grounding | Generally located in mountainous areas, the land is complex and rocky, with high soil resistivity and low grounding resistance requirements, generally below 0.5 ohms. Traditional methods cannot meet the requirements, so ion grounding is required. |

| Substation Grounding | Substation grounding generally requires resistance below 0.5 ohms. Traditional grounding construction is difficult and costly. Ion grounding is economical and effective. |

| Mobile Base Station Grounding | Many base stations are located in mountainous areas with complex soil conditions. Grounding resistance is generally required to be below 4 ohms. Ion grounding can achieve long-term stable and maintenance-free grounding. |

| Petrochemical Plant Grounding | For safety reasons, instruments and meters require high precision, and the grounding resistance must be low and stable. Ion grounding can meet these requirements. |

| Military Facility Grounding | Generally located in saline-alkali land, high-altitude rocky land, desert, etc., with complex geographical conditions, strict requirements for grounding resistance are required. Ion grounding can well meet the requirements. |

| Highway and Railway Grounding | Toll collection, signaling, monitoring systems, etc., can all use ion grounding. |

| Computer Room Grounding | Generally located in commercial centers, the grounding construction area is small, and the required grounding resistance is generally 1 ohm. If traditional methods are used, the area required is large and the construction is difficult. Ion electrode grounding can meet the requirements more easily. |

| Medical Equipment Grounding | The equipment is precision-grade, and the required grounding resistance is low, generally below 1 ohm, and the stability of the grounding resistance must be very high, without fluctuations. Traditional grounding is difficult to meet the requirements, so ion grounding is necessary. |

| Grounding of Scientific Research Equipment | Many precision instruments generally require a grounding resistance of around 2 ohms, which ion grounding can meet. |